Izingxenye zesithuthuthu se-aluminium alloyngokuvamile ukunikeza amandla kanye nesisindo esincane. Ingxubevange ye-Zinc ifanelana nokuma okuningiliziwe noma okuyinkimbinkimbiisithuthuthu die - cast izingxenye. AbaningiIsesekeli sesithuthuthu se-ODMabenzi bakhetha izinto ezisekelwe emsebenzini wengxenye. Ithebula elingezansi libonisa umehluko oyinhloko:

| Impahla | I-aluminium Alloy | I-Zinc Alloy |

|---|---|---|

| Amandla | Phezulu | Kuphakathi |

| Isisindo | Ukukhanya | Kusinda |

Okuthathwayo Okubalulekile

- Ingxube ye-aluminiuminikeza izingxenye eziqinile, ezingasindi ezilungele amafreyimu, amasondo, namakhava enjini, ukuthuthukisa isivinini sesithuthuthu nokubamba.

- Ingxubevange ye-Zinc ifanela izingxenye ezinemininingwane, ezinengcindezi ephansi njengezinsimbi nezingcezu zokuhlobisa, ezivumela umumo oyinkimbinkimbi nokukhiqiza okungabizi kakhulu.

- Ukukhetha ingxubevange efanele ngokusekelwe kumandla, isisindo, umklamo, izindleko, nendawo kusiza izingxenye zesithuthuthu zihlale isikhathi eside futhi zisebenze kangcono.

Amandla Nokuqina Ezingxenyeni Zesithuthuthu Die-Cast

I-Aluminium Alloy Amandla Nokuqina

I-aluminium alloy inikeza amandla aphezuluizingxenye zezithuthuthu ze-die-cast. Lokhu okubalulekile kungaphatha imithwalo esindayo kanye nemithelela enamandla. Onjiniyela abaningi bakhetha i-aluminium alloy ezingxenyeni ezidinga ukuhlala isikhathi eside. Insimbi imelana nokugoba nokuphuka ngaphansi kwengcindezi. Abagibeli bavame ukuthembela i-aluminium alloy kumafreyimu, amasondo, namakhava enjini. Lezi zingxenye kufanele zihlale ziqinile phakathi nokugibela okusheshayo kanye nemigwaqo emibi.

Ithiphu:I-aluminium alloy igcina amandla ayo ngisho nangemva kweminyaka eminingi yokusetshenziswa. Lokhu kukwenza kube ukukhetha okuhlakaniphile ezingxenyeni ezibhekana nokuguga kwansuku zonke.

I-Zinc Alloy Amandla Nokuqina

I-Zinc alloy inikeza amandla amaphakathiizingxenye zezithuthuthu ze-die-cast. Isebenza kahle ezingxenyeni ezingathwali imithwalo esindayo. I-Zinc alloy ingakha ubujamo obunemininingwane, okusiza lapho wenza izingxenye ezincane noma eziyinkimbinkimbi. Le nto ayinqamuki kalula, kodwa ingagoba uma iphushwa kakhulu. Abakhiqizi abaningi basebenzisa i-zinc alloy kuma-levers, amabakaki, namakhava. Lezi zingxenye azibhekene nengcindezi enkulu njengamafreyimu noma amasondo.

- I-Zinc alloy imelana nokuqhekeka ekusetshenzisweni okujwayelekile.

- Ingakwazi ukusingatha imithelela emincane ngaphandle kokulimala.

- Impahla isebenza kangcono ezingxenyeni ezidinga imininingwane emihle.

Ukusebenza ku-Real-World Motorcycle Applications

Izingxenye ze-die-cast yesithuthuthu kumele zisebenze kahle emgwaqeni. Izingxenye ze-aluminium alloy zivame ukuvela ezindaweni lapho amandla abaluleke kakhulu. Isibonelo, uhlaka lwesithuthuthu olwenziwe nge-aluminium alloy luhlala luqinile ngesikhathi sokujika okubukhali nokuma kungazelelwe. Abagibeli bazizwa bephephile ngalezi zingxenye ngoba awehluleki kalula.

Izingxenye ze-Zinc alloy zivela ezindaweni ezingafuneki kangako. I-handlebar switch noma ucezu lokunquma lokuhlobisa ngokuvamile lisebenzisa i-zinc alloy. Lezi zingxenye azibhekani namandla amaningi, ngakho amandla aphakathi anele. I-Zinc alloy iphinde ivumele imiklamo yokudala, esiza ngesitayela nokunethezeka.

Qaphela:Ukukhetha izinto ezifanele zengxenye ngayinye kusiza isithuthuthu ukuthi sihlale isikhathi eside futhi senze kangcono.

Isisindo kanye Nomphumela Wokusebenza Wezingxenye Zesithuthuthu Die-Cast

I-Aluminium Alloy Weight Izinzuzo

I-aluminium alloy igqama ngesisindo sayo esilula. Onjiniyela bavame ukukhetha le nto lapho befuna ukunciphisa isisindo sesithuthuthu. Izingxenye ezilula zisiza isithuthuthu ukuthi sihambe ngokushesha futhi sime ngokushesha. Abagibeli bayaqaphela ukuthi izithuthuthu ezinamafreyimu e-aluminium alloy noma amasondo azizwa kulula ukuwaphatha. Isisindo esiphansi siphinde sisho ukucindezelwa okuncane enjinini. Lokhu kungaholela ekusebenzeni kahle kukaphethiloli.

Ithiphu:Okululaisithuthuthu die - cast izingxenyekungenza ukugibela okude kungakhathali kubagibeli.

I-Zinc Alloy Weight Ukucatshangelwa

Ingxubevange ye-Zinc inesisindo esingaphezu kwe-aluminium alloy. Lesi sisindo esengeziwe singathinta indlela isithuthuthu esizizwa ngayo emgwaqeni. Izingxenye ezisindayo zingase zehlise ukusheshisa. Bangakwazi futhi ukwenza isithuthuthu sibe nzima ukusilawula ngesikhathi sokuphenduka okubukhali. Kodwa-ke, i-zinc alloy isebenza kahleizingxenye ezincane noma zokuhlobisalapho isisindo singenandaba kangako. Abakhiqizi basebenzisa i-zinc alloy ngezingcezu ezinjengezimpawu noma ukushintsha izindlu.

- I-Zinc alloy ifanela izingxenye ezingadingi ukukhanya.

- Isisindo esengeziwe singangeza ukuzinza kwezinye izingxenye ezincane.

Umthelela Ekuphatheni Nokusetshenzwa Kwezithuthuthu

Isisindo sengxenye ngayinye sishintsha indlela isithuthuthu esiphatha ngayo. Izingxenye ezilula ze-aluminium alloy zisiza isithuthuthu ukuthi siphendule ngokushesha esiqondisweni. Abagibeli bakuthola kulula ukujika ngokushesha noma ukuma kungazelelwe. Izingxenye ezisindayo ze-zinc alloy zingenza isithuthuthu sizinze kakhulu ngesivinini esiphansi, kodwa zinganciphisa ukusebenza kahle kukaphethiloli. Ukukhetha into efanele yengxenye ngayinye kusiza ukulinganisela isivinini, ukulawula, nokunethezeka.

Izindleko Nokukhiqiza Kahle Kwezingxenye Zesithuthuthu Die-Cast

I-Aluminium Alloy Cost Factors

Ingxubevange ye-aluminium ivamise ukubiza ngaphezu kwengxubevange ye-zinc. Intengo ivela kukho kokubili impahla eluhlaza kanye namandla adingekayo ukuze kuncibilike i-aluminium. Amafekthri adinga okokusebenza okukhethekile ukuze abambe indawo ephakeme yokuncibilika. Lokhu kunganyusa izindleko zokwenza izithuthuthu zife - izingxenye eziphonswe. Izibungu ze-aluminium nazo ziguga ngokushesha, ngakho izinkampani kufanele zishintshe kaningi. Lezi zici zenza i-aluminium alloy ibe utshalomali olukhulu kubakhiqizi.

I-Zinc Alloy Cost Factors

I-Zinc alloy ngokuvamile inikeza izindleko eziphansi zokukhiqiza. Insimbi iyancibilika lapho izinga lokushisa liphansi, eligcina amandla. Izimboni zingasebenzisa imishini engabizi kakhulu. Izibungu zeZinc zihlala isikhathi eside ngoba inqubo ithambile kumathuluzi. Lokhu kusiza ukugcina izindleko ziphansi zezingxenye ezincane noma eziyinkimbinkimbi. Izinkampani eziningi zikhetha i-zinc alloy lapho zifuna ukonga imali ngokusebenza kokukhiqiza okukhulu.

Ukuqhathaniswa Kwejubane Lokukhiqiza Nokuyinkimbinkimbi

I-Zinc alloy ivumela imijikelezo yokukhiqiza esheshayo. Insimbi iyaphola futhi iqine ngokushesha, ngakho izimboni zingenza izingxenye eziningi ngesikhathi esincane. I-Zinc iphinde igcwalise isikhunta kalula, esiza ngezimo ezinemininingwane. Ingxubevange ye-aluminium ithatha isikhathi eside ukuthi iphole futhi ingase idinge izinyathelo ezengeziwe zemiklamo eyinkimbinkimbi. Izinkampani kufanele zilinganise isivinini, izindleko, nengxenye yekhwalithi lapho zikhetha phakathi kwalezi zinto.

Ithiphu:Ukukhiqizwa okusheshayo nge-zinc alloy kungasiza ukuhlangabezana nezikhathi eziqinile zokufa kwezithuthuthu - izingxenye eziphonsiwe.

I-Surface Finish kanye nokumelana nokugqwala ezingxenyeni ze-Motorcycle Die-Cast

Ikhwalithi Yokuphezulu Kwe-Aluminium Alloy Nokuvikelwa

I-aluminium alloy inikeza indawo ebushelelezi nehlanzekile ezingxenyeni eziningi zezithuthuthu. Abakhiqizi bangapholisha noma bapende lezi zindawo ukuze zibukeke zicwebezela. Abanye basebenzisa i-powder coating ukwengeza ukuvikeleka okwengeziwe. Lokhu kunamathela kusiza ukuvimbela imihuzuko futhi kugcina ingxenye ibukeka iyintsha. I-aluminium alloy nayo yamukela i-anodizing, enezela ungqimba oluqinile ngaphandle. Lesi singqimba sivikela ukugqoka futhi sinikeza umbala ogqamile. Abagibeli bavame ukubona i-aluminium alloy ezingxenyeni ezibonakalayo ngoba ibukeka yesimanje futhi ihlala iheha.

Ithiphu:Izingxenye ze-aluminiyamu e-anodized zimelana nokufiphala nokunwaya kangcono kunensimbi engenalutho.

I-Zinc Alloy Surface Quality and Protection

Ingxubevange ye-Zinc idala ubujamo obunemininingwane eminingi kusithuthuthu - izingxenye eziphonsiwe. Ingaphezulu lizwakala libushelelezi futhi lingabonisa imigqa emihle noma amalogo. Abakhiqizi bavame ukusebenzisa i-chrome plating noma ukudweba ukuvikela i-zinc alloy. Lezi ziqephu zengeza ukukhanya futhi zisize ukumisa ukugqwala. Izingxenye ze-zinc alloy zingabukeka njengensimbi epholishiwe noma zibe nesiphetho se-matte. Ingaphezulu lihlala liqinile ekusebenziseni okuvamile, kodwa imihuzuko enzima ingase ibonakale kalula.

- Ingxubevange ye-Zinc isebenza kahle ezingxenyeni ezidinga umklamo omuhle noma oyinkimbinkimbi.

- I-Chrome plating inika isiphetho esifana nesibuko.

Ukuqhathaniswa Kokumelana Nokugqwala

I-aluminium alloy imelana nokugqwala kahle, ikakhulukazi ngemuva kwe-anodizing noma ukudweba. Yakha ungqimba oluncane lwe-oxide oluvimbela umswakama. Ingxubevange ye-Zinc iphinde ilwe nokugqwala, kodwa idinga isiphetho esihle sendawo ukuze uthole imiphumela engcono kakhulu. I-Chrome noma upende usiza izingxenye ze-zinc ukuthi zihlale isikhathi eside. Ezindaweni ezimanzi noma ezinosawoti, ingxubevange ye-aluminium ivamise ukuhlala isikhathi eside ngaphandle kokugqwala. Zombili izinto ezisetshenziswayo zidinga ukunakekelwa, kodwa ingxubevange ye-aluminium ivame ukunqoba ukuze isetshenziswe ngaphandle.

| Isici | I-aluminium Alloy | I-Zinc Alloy |

|---|---|---|

| Ukumelana Nokugqwala Kwemvelo | Phezulu | Kuphakathi |

| Idinga I-Coating Eyengeziwe | Ngezinye izikhathi | Ngokuvamile |

| Kungcono kakhulu kuzimo ezimanzi | Yebo | Ngezinye izikhathi |

Ukufaneleka Isicelo Sezithuthuthu Die-Cast Izingxenye

Ukusetshenziswa Okungcono Kakhulu Kwe-Aluminium Alloy Ezithuthuthu

Ingxubevange ye-aluminium ilingana kahle ezingxenyeni ezidinga ukuqina futhi zilula. Onjiniyela bavame ukukhetha le nto yohlaka oluyinhloko lwesithuthuthu. Uhlaka lusekela umgibeli kanye nenjini, ngakho-ke kufanele isingathe imithwalo esindayo namandla aqinile. I-aluminium alloy nayo isebenza kahle kumasondo. Lawa masondo asiza isithuthuthu ukuthi sihambe ngokushesha futhi sime ngokushesha. Abagibeli babona ukuphatha okungcono uma amasondo enesisindo esincane.

Okunye ukusetshenziswa okuhle kwe-aluminium alloy kufaka phakathi:

- Ama-swingarm, axhuma isondo langemuva kuhlaka.

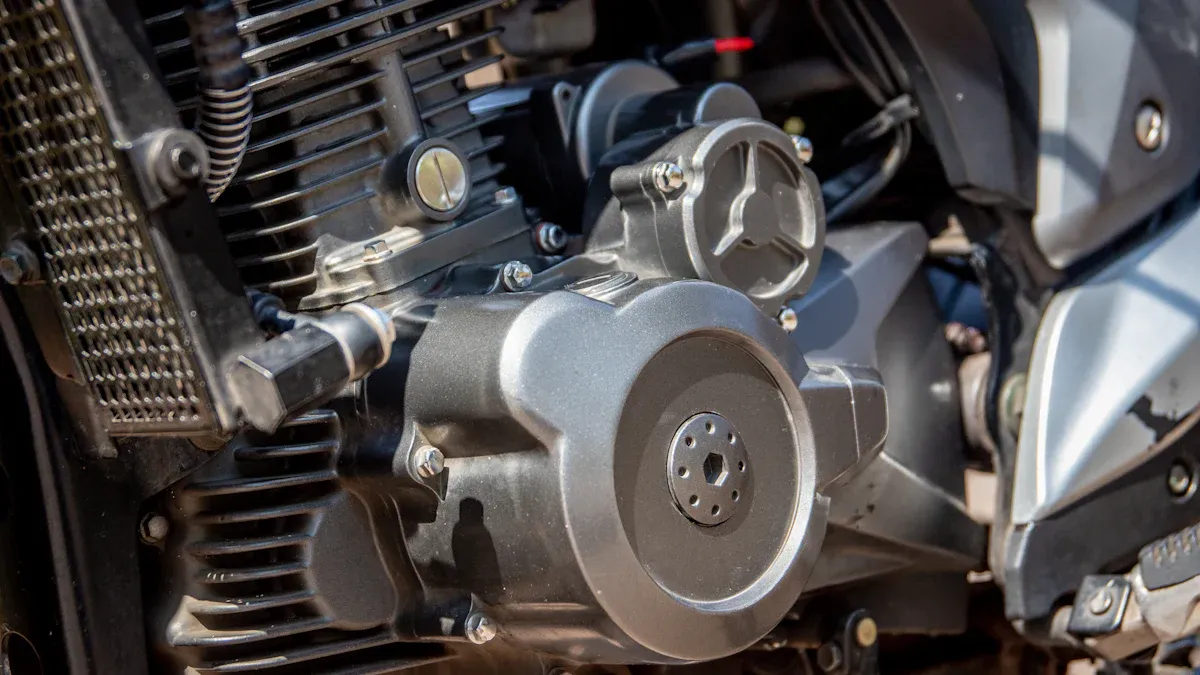

- Izembozo zenjini, ezivikela izingxenye ezibalulekile ekungcoleni nasekulimaleni.

- Izikhonkwane zezinyawo nezibambo, ezidinga ukuba kokubili ziqine futhi zilula.

Qaphela:I-aluminium alloy isiza ukunciphisa isisindo esiphelele sesithuthuthu. Lokhu kwenza ukugibela kube lula futhi kube lula ukukulawula.

Ukusetshenziswa Okungcono Kakhulu Kwe-Zinc Alloy Ezithuthuthu

Ingxubevange ye-Zinc ifanela izingxenye ezinobunjwa obuyinkimbinkimbi noma ezidinga imininingwane emihle. Abakhiqizi bavame ukusebenzisa i-zinc alloy ezingxenyeni ezincane ezingabhekene nokucindezeleka okukhulu. Isibonelo, ama-levers kanye namabakaki enziwe nge-zinc alloy angaba nemiklamo enemininingwane. Lezi zingxenye azithwali imithwalo esindayo, ngakho amandla aphakathi anele.

Ukusetshenziswa okujwayelekile kwe-zinc alloy kufaka:

- Izingcezu zokunquma zokuhlobisa, njengezifanekiselo noma amabheji.

- Shintsha izindlu nezinkinobho zokulawula.

- Amakhava amancane nabakaki ababamba izintambo noma izintambo.

Ingxubevange yeZinc nayo isebenza kahle ezingxenyeni ezidinga indawo ebushelelezi noma isiphetho esicwebezelayo. Ukufakwa kwe-Chrome ku-zinc alloy kunikeza ukubukeka okufana nesibuko, okuthandwa ngabagibeli abaningi.

Izibonelo Zomhlaba Wangempela Zezingxenye Zokufa Kwezithuthuthu

Izithuthuthu eziningi zisebenzisa kokubili i-aluminium alloy ne-zinc alloy ezindaweni ezahlukene. Impahla ngayinye ilingana nomsebenzi okhethekile. Nazi izibonelo zomhlaba wangempela:

| Ingxenye Igama | I-Common Material | Isizathu Sokukhetha |

|---|---|---|

| Uhlaka Oluyinhloko | I-aluminium Alloy | Idinga amandla aphezulu kanye nesisindo esincane |

| Amasondo amasondo | I-aluminium Alloy | Ithuthukisa isivinini nokuphatha |

| Ikhava Yenjini | I-aluminium Alloy | Ivikela injini, imelana nomthelela |

| Ukushintsha kwe-Handlebar | I-Zinc Alloy | Ivumela umumo onemininingwane |

| Uphawu Lokuhlobisa | I-Zinc Alloy | Idinga imininingwane emihle kanye nesiphetho esibushelelezi |

| I-Brake Lever | I-Zinc Alloy | Iphatha ingcindezi elula, enemininingwane |

Ithiphu:Abenzi bezithuthuthu bakhetha ukwaziswa okusekelwe emsebenzini ngamunye okufanele wenziwe. Ukusebenzisa ingxubevange efanele kuyasizaisithuthuthu die - cast izingxenyehlala isikhathi eside futhi usebenze kangcono.

Umhlahlandlela Wesinqumo Esisebenzayo Wokukhetha Izingxenye Zezingxenye Zezithuthuthu Ezifayo

Uhlu Lokuhlola Lokukhetha Ingxubevange Elungile

Ukukhetha impahla engcono kakhulu yezingxenye zesithuthuthu kungazizwa kuyinselele. Uhlu lokuhlola olulula lusiza ukwenza inqubo ibe lula. Nanka amaphuzu abalulekile okufanele uwacabangele:

- Izidingo Zamandla: Nquma ukuthi ingxenye kufanele iphathe imithwalo esindayo noma imithelela.

- Isisindo Ukubaluleka: Cabanga ukuthi isisindo sengxenye sithinta kangakanani ukusebenza.

- Ingxenye Eyinkimbinkimbi: Hlola ukuthi ingabe ingxenye inemininingwane emihle noma izimo eziyinkimbinkimbi.

- Imikhawulo Yezindleko: Setha ibhajethi yezinto zokwakha nokukhiqiza.

- I-Surface Qeda: Khetha uma ingxenye idinga ukubukeka okucwebezelayo, okubushelelezi, noma okunemininingwane.

- Ukumelana Nokugqwala: Cabangela ukuthi ingxenye izobhekana yini nemvula, udaka, noma imigwaqo enosawoti.

- Isivinini Sokukhiqiza: Nquma ukuthi ukukhiqiza ngokushesha kubalulekile.

Isikhathi sokuthumela: Jul-18-2025