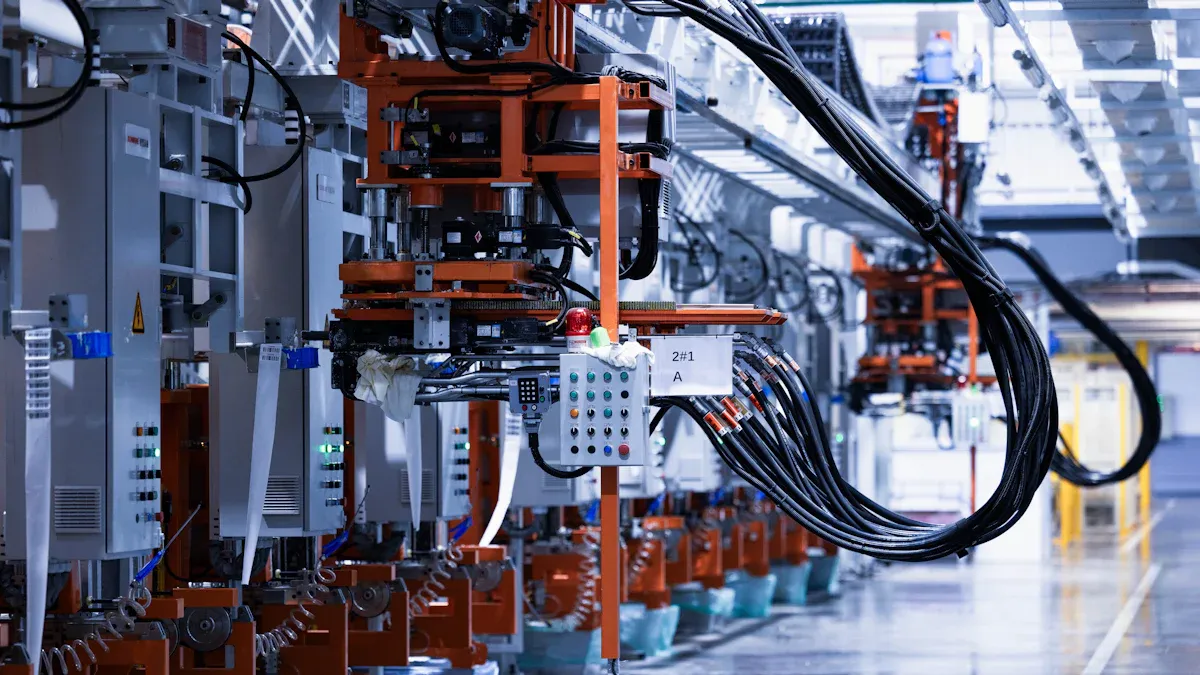

Umatshini we-CNC uguqula imveliso yeendawo ezisecaleni ngokuqinisekisa ukuchaneka okungahambelaniyo. Unokuthembela kule nkqubo ukuphelisa impazamo yomntu kwaye ufezekise umgangatho ohambelanayo kuwo onke amaqhekeza. Ngokusebenzisa inkqubo ephezulu kunye ne-automation, oomatshini be-CNC balandela iinkcukacha ezichanekileyo, behambisa iziphumo ezihlangabezana nokunyamezela okuqinileyo. Nokuba kuyilwa uyilo oluntsonkothileyo okanye uphucula iinkqubo zokwenziwa, umatshini weCNC ubonelela ngezisombululo ezithembekileyo. Amashishini afanaOEM aluminiyam die castingbaxhamle kubuchule bokuvelisa amacandelo angenasiphako, anje ngamagquma ezithuthuthu zokufa, ngamaxabiso akhuphisanayo. Ukuthi ngqo,china OEM aluminiyam die castinguye waba ngumdlali ophambili ekuhambiseni iimveliso ezikumgangatho ophezulu ngelixa ugcina iindleko-ukusebenza, ngakumbi xa kuziwafa ukuphosa ixabiso isithuthuthu cover.

Izinto eziphambili zokuThatha

- CNC machining isusa iimpazamo zabantu, ukwenza iinxalenye ngeukuchaneka okukhulu.

- Ukuzenzekela kuvumela oomatshini be-CNC basebenze ngokungapheliyo ngaphandle kokudinwa. Oku konga ixesha kunye nezixhobo ngelixa zihlala zichanekile.

- Oomatshini be-Multi-axis banokwenza uyilo olukhohlisayo ukuba iindlela zakudala zingenako. Oku kuqinisekisa ukuba iindawo zingena ngokugqibeleleyo kwiindibano.

- Izixhobo zokusika ezilungileyo zibalulekile kwiinqununu ezigudileyo kunyeubungakanani obuchanekileyo. Oku kuphucula indlela imveliso yokugqibela isebenza ngayo.

- Abahloli bexesha lokwenyani banika uhlaziyo olukhawulezayo ngexesha lemveliso ukubamba iimpazamo kwangethuba kwaye ugcine umgangatho uzinzile.

Iindlela ezingundoqo zokuchaneka kwi-CNC Machining

Ukuzenzekela kunye nendima yayo ekunciphiseni impazamo yabantu

I-Automation idlala indima ebalulekileyo kumatshini we-CNC ngokuphelisa ukungahambelani okubangelwa yimisebenzi yezandla. Xa uthembele kwiinkqubo ezizenzekelayo, umatshini uqhuba inyathelo ngalinye lenkqubo ngokuthe ngqo. Oku kunciphisa amathuba eempazamo ezidla ngokwenzeka xa abantu besenza imisebenzi ephindaphindwayo.

Ingcebiso:I-automation iqinisekisa ukuba yonke intoIphathi esecalenieveliswayo ihambelana noyilo lokuqala, nakwimveliso emikhulu.

Oomatshini be-CNC balandela imiyalelo ecwangciswe kwangaphambili, nto leyo ethetha ukuba akufuneki ukhathazeke malunga nokwahluka phakathi kwamalungu. Inkqubo ivumela kwakhona ukusebenza ngokuqhubekayo ngaphandle kokukhathala, ukuqinisekisa umgangatho ohambelanayo. Umzekelo:

- Imisebenzi ephindaphindiweyonjengokugrumba okanye ukusika kwenziwa ngokuchaneka okufanayo ngalo lonke ixesha.

- Imisebenzi entsonkothileyoziphathwa ngokulula, njengoko umatshini ungaphambuki kwindlela yawo ecwangcisiweyo.

Ngokunciphisa ukubandakanyeka kwabantu, ukuzenzekelayo akuphuculi nje ukuchaneka kodwa kusindisa ixesha kunye nezixhobo.

Izakhono ezininzi ze-axis zejometri ezinzima

Oomatshini be-CNC abanezakhono ezininzi ze-axis banokuphatha uyilo oluntsonkothileyo olungenakwenzeka ngeendlela zemveli. Aba matshini bahamba ngeendlela ezininzi, kukuvumela ukuba wenze iinxalenye ezinemilo enzima kunye nee-engile.

Yiba nomfanekiso uzama ukuqingqa into ye-3D ngesandla. Kuya kuthatha iiyure, kwaye iziphumo zisenokungafezeki. Oomatshini be-CNC be-Multi-axis basombulula le ngxaki ngokunikezela:

- 3-axis machiningkwimisebenzi esisiseko efana nokugrumba kunye nokusila.

- I-5-axis okanye ngaphezulukwimisebenzi ephezulu, efana nokudala imiphezulu egobileyo okanye iindlela zangaphantsi.

Phawula:I-Multi-axis machining ibalulekile kumashishini afana ne-aerospace kunye neemoto, apho ukuchaneka kunye nobunzima buhamba kunye.

Ngobu buchule, unokuvelisaIphathi ezisecaleniezingena ngokugqibeleleyo kwiindibano ezintsonkothileyo. Oku kuqinisekisa ukuba icandelo ngalinye lisebenza ngaphandle komthungo kunye nenkqubo yonke.

Isoftware yeCAD/CAM yoguqulelo oluchanekileyo lokuyilwa ukuya kwimveliso

I-CAD (i-Computer-Aided Design) kunye ne-CAM (i-Computer-Aided Manufacturing) i-software ivala umsantsa phakathi kweengcamango zakho kunye nemveliso yokugqibela. Ezi zixhobo zikuvumela ukuba uyile iindawo ezineenkcukacha ezimangalisayo kwaye emva koko uguqule ezo ziyilo zibe yimiyalelo efundeka ngoomatshini.

Xa usebenzisa isoftware yeCAD/CAM, ufumana iingenelo ezininzi:

- Ukuchaneka kuyilo:Unokwenza iimodeli ezineenkcukacha ze-3D ezinobungakanani obuchanekileyo.

- Indibaniselwano engenamthungo:Isoftware iqinisekisa ukuba uyilo luguqulela ngokugqibeleleyo kwinkqubo yomatshini.

- Ukufunyanwa kwempazamo:Ichonga imiba enokubakho ngaphambi kokuba imveliso iqale, okongela ixesha kunye nemathiriyeli.

Umzekelo, ukuba uyila indawo esecaleni enokunyamezelana okuqinileyo, isoftware yeCAD/CAM iqinisekisa ukuba yonke imilinganiselo ichanekile. Umatshini ke ulandela le miyalelo ukuze uvelise indawo ehambelana neenkcukacha zakho.

Inyani eyolisayo:Isoftware yeCAD/CAM inokulinganisa inkqubo yomatshini, ikuvumela ukuba ubone indlela inxalenye eya kujongeka ngayo phambi kokuba yenziwe.

Ngokudibanisa isoftware ephucukileyo kunye neCNC machining, ungafikelela kwinqanaba lokuchaneka elalikade lingenakucingelwa.

Iimpawu zobuChwephesha bokuphucula ukuchaneka

Izixhobo zokusika ezikumgangatho ophezulu kunye nefuthe labo ekuchanekeni

Izixhobo zokusika ozikhethayo zidlala indima ebalulekileyo ekuqinisekiseni ukuchaneka komatshini we-CNC. Izixhobo ezikumgangatho ophezulu ziqinisekisa ukusikwa okucocekileyo, ukunciphisa ukuguqulwa kwezinto, kunye nokugcina ukunyamezela okuqinileyo. Xa usebenzisa izixhobo ze-subpar, iziphumo zihlala zibandakanya imiphetho erhabaxa, ukungachaneki komda, kunye nokwanda kokunxiba kumatshini.

Nasi isizathu sokuba izixhobo zokusika ezikumgangatho ophezulu zibalulekile:

- Imiphetho ebukhali: Ezi zixhobo zisika izinto ngokucocekileyo, zishiya iindawo ezigudileyo.

- Izinto ezihlala ixesha elide: Izixhobo ezenziwe kwi-carbide okanye idayimani zihlala ixesha elide kwaye zixhathisa ukunxiba, ziqinisekisa ukusebenza okufanayo.

- Ukungcangcazela okucuthiweyo: Izixhobo ezikumgangatho ophezulu zinciphisa ukungcangcazela, ezinokubangela ukungachaneki ngexesha lomatshini.

Ingcebiso:Hlola rhoqo kwaye ubeke izixhobo zokusika ukuze ugcine ukuchaneka. Izixhobo ezigugileyo zinokubeka esichengeni umgangatho wamalungu akho asecaleni.

Umzekelo, ukuba ukhonamachining amacandelo aluminiyam, usebenzisa isixhobo esinomgca osikiweyo osikiweyo ukhusela i-burrs kwaye uqinisekisa ukugqitywa okungenasiphako. Le ngqalelo kwiinkcukacha ichaphazela ngokuthe ngqo ukusebenza kunye nokuthembeka kwemveliso yokugqibela.

Ukukhethwa kwezinto eziphathekayo kunye nempembelelo yayo ekuchanekeni komatshini

Iizinto ozikhethayongokuba machining kuchaphazela kakhulu ukuchaneka kwemveliso yokugqibela. Izinto ezahlukeneyo zineempawu ezikhethekileyo, ezifana nobunzima, i-ductility, kunye ne-thermal conductivity, echaphazela indlela abasabela ngayo kumandla okusika.

Qwalasela le miba xa ukhetha imathiriyeli:

- Ukuqina: Izinto ezilukhuni, njengensimbi engenasici, zifuna izixhobo ezikhethekileyo kunye nesantya esincinci sokusika ukufezekisa ukuchaneka.

- Ukwandiswa kweThermal: Izinto eziye zanda phantsi kobushushu, njengeeplastiki, zifuna ukulawulwa kweqondo lokushisa ngononophelo ngexesha lomatshini.

- Ubuchule: Ezinye izinto, ezifana ne-aluminium, kulula ukuzisebenzisa kwaye zivelise iziphumo ezichanekileyo xa kuthelekiswa ne-alloys eqinile.

Phawula:Soloko uthelekisa imathiriyeli nesicelo. Umzekelo, izinto ze-aerospace zihlala zifuna izinto ezikhaphukhaphu kodwa ezomelele njenge-titanium, ezifuna iindlela ezichanekileyo zobuchule bomatshini.

Ngokuqonda iipropathi zezinto ozikhethileyo, unokwandisa inkqubo yomatshini ukufezekisa inqanaba eliphezulu lokuchaneka.

Ukubeka iliso ngexesha lokwenyani kunye neenkqubo zengxelo

Iinkqubo zokubeka iliso zexesha lokwenyani ziguqula ukwenziwa kwe-CNC ngokubonelela ngengxelo ekhawulezileyo ngexesha lenkqubo yokuvelisa. Ezi nkqubo zilandelela izinto eziguquguqukayo ezifana nesantya sokusika, ukunxiba kwesixhobo, kunye nokungcangcazela koomatshini, ziqinisekisa ukuba umsebenzi ngamnye uhlala ngaphakathi kweeparamitha ezifunekayo.

Nantsi indlela ukujonga ixesha lokwenyani kuphucula ukuchaneka:

- Ukufunyanwa kwempazamo: Abenzi boluvo bachonga ukunxaxhile kwindlela ecwangcisiweyo kwaye bakulumkise ngoko nangoko.

- Ukubeka iliso kwimeko yesixhobo: Inkqubo ilandelela ukunxiba kwesixhobo kwaye icebisa ukutshintshwa ngaphambi kokuba umgangatho uthotyelwe.

- Uhlengahlengiso oluziqhelanisayo: Oomatshini banokuhlengahlengisa ngokuzenzekelayo isantya sokusika okanye amazinga okutya ukugcina ukuchaneka.

Inyani eyolisayo:Abanye oomatshini be-CNC abaphambili basebenzisa iisistim zokubek' iliso ezinikwe amandla e-AI ukuqikelela imiba enokubakho ngaphambi kokuba yenzeke.

Umzekelo, ukuba isixhobo siqala ukuguga ngexesha lemveliso, inkqubo yokubeka iliso inokumisa umsebenzi kwaye ikwazise. Oku kuthintela iziphene kwaye kuqinisekisa ukuba yonke indawo esecaleni idibana neenkcukacha zakho.

Ngokusebenzisa iliso lexesha langempela, unokugcina umgangatho ohambelanayo kunye nokunciphisa umngcipheko weempazamo, nakwimveliso ephezulu.

Iingenelo zokuchaneka kwiiNdawo eziSpare

Ukuhambelana kwimveliso yemveliso enkulu

Ukuchaneka kumatshini we-CNC kuqinisekisa ukuba yonke indawo oyivelisayo ihambelana noyilo lwangaphambili, nakwimveliso ephezulu. Oku kungaguquguquki kubalulekile xa kufuneka ufezekise ixesha elibekiweyo okanye uhambise inani elikhulu lamalungu ngaphandle kokubeka esichengeni umgangatho.

Xa uthembele kumatshini we-CNC, inkqubo iphelisa ukwahluka phakathi kwamacandelo. Icandelo ngalinye liyafana, liqinisekisa indibaniselwano engenamthungo kwiindibano ezinkulu. Umzekelo:

- Iindawo zemoto: Yonke igiya okanye icandelo le-injini lilingana ngokugqibeleleyo, linciphisa ixesha lokuhlanganisa.

- Electronics: Iibhodi zeesekethe zigcina ukufana, ziqinisekisa ukusebenza okuthembekileyo.

Ingcebiso:Ukungaguquguquki kwimveliso yakha ukuthembela kubathengi bakho, njengoko banokuxhomekeka kuwe kwiimveliso ezithembekileyo, ezikumgangatho ophezulu.

Ngokugcina ukufana, ukwenziwa komatshini weCNC kukunceda ukhulise imveliso ngelixa udibana nemigangatho yoshishino.

Ukunciphisa iziphene kunye nenkunkuma, ekhokelela ekusebenzeni kakuhle kweendleko

Iziphene kunye nenkunkuma yezinto eziphathekayo kunokunyusa kakhulu iindleko zemveliso.CNC machiningyenza le miba ibe ncinane ngokulandela imiyalelo echanekileyo kunye nokusebenzisa iinkqubo zokubeka iliso eziphezulu. Oku kuqinisekisa ukuba inxalenye nganye ihlangabezana neenkcukacha zakho ngaphandle kweempazamo.

Nantsi indlela ukuchaneka okuyinciphisa ngayo inkunkuma:

- Ukusikwa okuchanekileyo: Umatshini ususa kuphela izinto eziyimfuneko, ungashiyi ukugqithisa.

- Uthintelo lwempazamo: Ukubeka iliso ngexesha lokwenyani kukhangela imiba kwangethuba, kuthintela iindawo ezineziphene.

Inyani eyolisayo:Iinkampani ezisebenzisa i-CNC machining zihlala zinika ingxelo ukuya kuthi ga kwi-30% yokunciphisa inkunkuma yezinto eziphathekayo xa kuthelekiswa neendlela zemveli.

Ngokunciphisa iziphene, ulondoloza kwizinto eziluhlaza kunye neendleko zokuphinda usebenze kwakhona. Oku kusebenza kakuhle kuguqulela kwingeniso ephezulu kunye nenkqubo yemveliso ezinzileyo.

Ukuhambelana noyilo oluntsonkothileyo kunye nesiko

Umatshini we-CNC ugqwesa ekuveliseni iindawo ezinejometri ezintsonkothileyo kunyeiinkcukacha zesiko. Nokuba wenza iipateni ezintsonkothileyo okanye uyilo olulodwa, inkqubo iqinisekisa ukuba zonke iinkcukacha zichanekile.

Umzekelo, ukuba ufuna indawo esecaleni enokunyamezelana okuqinileyo okanye iimilo ezingaqhelekanga, oomatshini be-CNC banokuwusingatha umceli mngeni. Ubuchule be-multi-axis bukuvumela ukuba wenze ii-undercuts, umphezulu ogobileyo, kunye nezinye izinto ezintsonkothileyo ngokulula.

Phawula:Uyilo oluqhelekileyo luxabiseke ngakumbi kumashishini afana ne-aerospace, apho ukuchaneka kunye nokuveliswa kwezinto ezintsha kuhamba kunye.

Ngokunikezela ngokuhambelana noyilo oluntsonkothileyo, umatshini weCNC uxhobisa ukuba uhlangabezane neemfuno ezizodwa ngaphandle kokuncama umgangatho.

OEM Aluminiyam Die Casting kunye CNC Machining

Umatshini we-CNC wonyusa njani ukuchaneka kwi-aluminium die casting

CNC machiningidlala indima ebalulekileyo ekuphuculeni ukuchaneka kwe-aluminium die casting. Xa udibanisa i-CNC machining kunye ne-die casting, ufumana ukukwazi ukucokisa amacandelo ukuhlangabezana nemigaqo echanekileyo. Emva kwenkqubo yokuqala yokuphosa, oomatshini be-CNC basusa izinto ezingaphezulu kunye nemigangatho egudileyo, beqinisekisa ukuba indawo nganye ihambelana noyilo lwakho.

Ungathembela kumatshini we-CNC ukulungisa ukungafezeki okwenzeka ngokwemvelo ngexesha lokuphosa. Ngokomzekelo, isusa i-burrs kunye neencam ezibukhali, ishiya isiphelo esingenasiphako. Le nkqubo ikwakuvumela ukuba wenze iimpawu ezintsonkothileyo ezifayo kuphela ezingenakufezekiswa.

Ingcebiso:I-CNC machining iqinisekisa ukuba iinxalenye ze-aluminiyam ezifayo zidibana nemigangatho ephezulu yokuchaneka, izenza zilungele amashishini afana neenqwelo-moya kunye ne-aerospace.

Ukunyamezelana okuqinileyo kumacandelo e-OEM aluminiyam

Ukunyamezelana okuqinileyo kubalulekile kwi-OEM aluminium die casting. CNC machining iqinisekisa ukuba onke amacandelo abambelela kwezi mfuno zingqongqo. Ngokulandela imiyalelo ecwangciswe kwangaphambili, umatshini uvelisa iinxalenye ezinemilinganiselo engaguqukiyo, nakwiziyilo ezintsonkothileyo.

Xa ufuna amacandelo e-aluminium kwizicelo ze-OEM,ukuchaneka kuba yinto engenakuxoxisana. Umatshini we-CNC uqinisekisa ukuba inxalenye nganye ingena ngokugqibeleleyo kwindibano yayo. Oku kunciphisa umngcipheko wokungasebenzi kakuhle kunye nokuphucula ukuthembeka kwemveliso jikelele.

Umzekelo, ukuba wenza izigqubuthelo zenjini okanye izibiyeli, umatshini weCNC uqinisekisa ukuba isiqwenga ngasinye silungelelaniswa ngaphandle komthungo namanye amalungu. Eli nqanaba lokuchaneka likunceda ukuba uhlangabezane nemigangatho yoshishino kunye nokulindelwe ngabathengi.

Ukuqinisekisa ukuphinda-phinda kunye nomgangatho kwiindawo zokufa

Ukuphinda-phinda kubalulekile xa uvelisa izixa ezikhulu zamalungu e-die-cast. Umatshini we-CNC uyagqwesa ekunikezeni iziphumo ezingaguqukiyo, eqinisekisa ukuba icandelo ngalinye lihambelana noyilo lokuqala. Unokuxhomekeka kule nkqubo ukugcina umgangatho kuyo yonke imveliso yemveliso emininzi.

Iinkqubo zokubeka iliso zexesha lokwenyani koomatshini be-CNC ziphucula ngakumbi ukuphinda-phinda. Ezi nkqubo zifumanisa ukunxaxha kwaye zenze uhlengahlengiso ukugcina imisebenzi isendleleni. Ngenxa yoko, ugwema iziphene kwaye ugcine imigangatho ephezulu yomgangatho.

Inyani eyolisayo:CNC machining ivumela abavelisi ukuba bavelise iinxalenye ezifanayo kunye nenkunkuma encinci, iyenza ibe sisisombululo esineendleko ezifanelekileyo ze-OEM aluminium die casting.

Ngokudibanisa umatshini we-CNC kunye nokuphosa ukufa kwe-aluminium, ufezekisa ukuchaneka, ukuphindaphinda, kunye nomgangatho, ukuqinisekisa ukuba iimveliso zakho zibalasele kwiimarike ezikhuphisanayo.

ImiSebenzi yoQinisekiso loMgangatho kwi-CNC Machining

Ubuchule bokuhlola obufana nokulungelelanisa oomatshini bokulinganisa (CMM)

Ukuhlola linyathelo elibalulekileyo ekuqinisekiseni ukuchaneka kweengxenye ze-CNC ezinomatshini. Esinye sezona zixhobo zisebenzayo kule nto yi-coordinate measuring machine (CMM). Ungasebenzisa i-CMM ukulinganisa imilinganiselo yenxalenye ngokuchaneka okugqithisileyo. Isebenza ngokusebenzisa iprobe ukuze ichukumise iindawo ezahlukeneyo kumphezulu wenxalenye, isenza imephu eneenkcukacha yejometri yayo.

Ii-CMM zikunceda uqinisekise ukuba indawo nganye iyahambelana noyilo lwakuqala. Umzekelo, ukuba uvelisa amacandelo eOEM aluminiyam die casting, i-CMM iqinisekisa ukuba isiqwenga ngasinye sihlangabezana nokunyamezela okufunekayo. Eli nqanaba lokuchaneka linciphisa umngcipheko weziphene kwaye liqinisekisa ukuhambelana nezinye iindawo.

Ingcebiso:Rhoqo hlengahlengisa iCMM yakho ukuze igcine ichanekile kunye nokuthembeka kwayo.

Ukuhlolwa kwenkqubo ukuqinisekisa ukuthotyelwa kwemigaqo

Ukubeka iliso kwinkqubo yomatshini ngexesha lokwenyani kubalulekile ekugcineni umgangatho. Oomatshini be-CNC abakwinqanaba eliphezulu beza bexhotyiswe ngezixhobo zoluvo ezilandelela izinto eziguquguqukayo ezifana nesantya sokusika, ukunxitywa kwesixhobo, kunye nobushushu. Ezi sistim zikwazisa ngako nakuphi na ukutenxa kwiinkcukacha ezicwangcisiweyo.

Umzekelo, ukuba usenza iinxalenye ze-OEM yokuphosa i-aluminium yokufa, ukujonga inkqubo kuqinisekisa ukuba icandelo ngalinye lithobela imigangatho efunekayo. Oku kunciphisa ukubakho kweempazamo kwaye kunciphisa inkcitho yezinto eziphathekayo. Ngokubeka iliso elibukhali kwinkqubo, unokugcina umgangatho ongaguqukiyo kuyo yonke imisebenzi yokuvelisa.

Inyani eyolisayo:Abanye oomatshini be-CNC basebenzisa i-AI ukuqikelela imiba enokubakho ngaphambi kokuba yenzeke, bephucula ngakumbi ukuchaneka.

Ukuphuculwa okuqhubekayo ngokuhlalutya idatha

Uhlalutyo lwedatha ludlala indima ephambili ekuphuculeni umgangatho we-CNC machining ngokuhamba kwexesha. Ngokuqokelela idatha kwimveliso nganye, unokuchonga iipateni kunye neendawo zokuphucula. Umzekelo, ukuhlalutya idatha yokunxiba isixhobo kunokukunceda ukuba wenze iishedyuli zokutshintsha isixhobo, unciphise ixesha lokuphumla kunye nokuphucula ukusebenza kakuhle.

Xa ukuvelisa iinxalenye ze-aluminium ye-OEMukuphosa ukufa, uhlalutyo lwedatha lukunceda ukuba usulungekise iinkqubo zakho ukuze ufezekise ukunyamezela ngakumbi. Oku kuqinisekisa ukuba iimveliso zakho zihlala zikhuphisana kwimarike. Ngokuqhubeka uphucula, unokuzisa iinxalenye ezikumgangatho ophezulu ngelixa unciphisa iindleko.

Phawula:Sebenzisa izixhobo zesoftware ukwenza uqokelelo lwedatha ngokuzenzekelayo kunye nohlalutyo lokuqonda oluchanekileyo.

Umatshini we-CNC uguqula indlela owenza ngayo iinxalenye ezisecaleni. Isebenzisa i-automation kunye netekhnoloji ephezulu ukuhambisa ukuchaneka okungahambelaniyo, iqinisekisa ukuba yonke into idibana nokunyamezelana. Ungathembela kule nkqubo ukuvelisa iziphumo ezingaguqukiyo, ezikumgangatho ophezulu, nakuyilo oluntsonkothileyo.

Ingcebiso:Amashishini afana ne-aerospace kunye neemoto zixhomekeke kumatshini we-CNC ukunciphisa iziphene kunye nokuphucula ukuthembeka.

Ngokwamkela oomatshini be-CNC, uphucula ukusebenza kakuhle, ukunciphisa inkcitho, kwaye uhlangabezane neenkcukacha eziyimfuneko. Oku kuyenza ibe sisixhobo esiyimfuneko kumashishini afuna ukuchaneka kunye nokungaguquguquki.

FAQ

1. Ngawaphi amashishini azuza kakhulu kubuchwephesha be-CNC?

CNC machining isetyenziswa ngokubanzi kwi aerospace, iimoto, elektroniki, kunye namashishini zonyango. Unokuthembela kuyo ukuvelisa amacandelo achanekileyo oyilo oluyinkimbinkimbi, ukuqinisekisa ukuthembeka kunye nokusebenza kwizicelo ezibalulekileyo.

2. Umatshini we-CNC unciphisa njani iindleko zemveliso?

Inciphisa inkcitho yezinto eziphathekayo kunye neziphene ngokulandela iinkcukacha ezichanekileyo. Wonga imali ngokunqanda ukuphinda usebenze kunye nokwandisa ukusetyenziswa kwezinto ezikrwada. Oku kusebenza kakuhle kwenza ukuba oomatshini be-CNC bangabizi kakhulu kwimveliso enkulu.

3. Ngaba oomatshini be-CNC banokuphatha uyilo lwesiko?

Ewe, oomatshini be-CNC bayagqwesa ekudaleni uyilo oluntsonkothileyo nolwesiko. Unokuzicwangcisa ukuba zivelise iijiyometri ezizodwa kunye nokunyamezelana okuqinileyo, uqinisekisa ukuhambelana neemfuno ezizodwa.

4. Zeziphi izinto ezisebenza kakuhle ngomatshini we-CNC?

Ialuminiyam, intsimbi, ititanium, kunye neeplastiki zisetyenziswa ngokuqhelekileyo. Kuya kufuneka ukhethe imathiriyeli ngokusekwe kwiimfuno zesicelo sakho, njengokuqina, ubunzima, okanye ukusebenziseka.

5. Iinkqubo zokubeka iliso ngexesha langempela ziphucula njani ukuchaneka?

Ezi nkqubo zilandelela izinto eziguquguqukayo ezifana nokunxiba kwesixhobo kunye nesantya sokusika. Bakulumkisa ngokunxaxha kwaye wenze uhlengahlengiso ukugcina ukuchaneka, uqinisekisa umgangatho ongaguqukiyo kuyo yonke imveliso eqhutywayo.

Ixesha lokuposa: Jun-04-2025