Likarolo tsa ho lahla tsa tšepe tsa setsebili bohlokoa bakeng sa ho hlahisa likarolo tsa boleng bo holimo ka nepo e ke keng ea lekanngoa. Liindasteri tse sa tšoaneng li itšetlehile kametal die castmokhoa oa ho tšoarella, scalable, le litharollo tse bolokang chelete e ngata. Sistimi ea othomathike e bapala karolo ea bohlokoa ho ntlafatseng boleng ka ho lekola mefuta e kang lebelo la tšepe le khatello ea haeteroliki. Litheknoloji tsena tse tsoetseng pele li tiisa liphetho tse tsitsitseng, ho etsa hore hometal die casting parts foundrykarolo ea bohlokoa ea tlhahiso ea sejoale-joale.

Lintlha tsa bohlokoa

- Metal die castinge etsa likarolo tse matla ka ho sututsa tšepe e chesang hore e be hlobo.

- Ho khethathepa e ntle, joalo ka aluminium kapa magnesium, e etsa hore likarolo li sebetse hantle 'me li tšoarelle nako e telele.

- Ho sebelisa mechini ho boloka nako le chelete, e thusang liindasteri tse kholo joalo ka baetsi ba likoloi le lifofane.

Utloisisa Metal Die Casting Parts

Metal Die Casting ke eng?

Metal die casting ke ts'ebetso ea tlhahiso e hlahisang likarolo tsa tšepe tse nepahetseng le tse tšoarellang. E akarelletsa ho kenya tšepe e qhibilihisitsoeng ka har'a hlobo, kapa ho shoa, tlas'a khatello e phahameng. Mokhoa ona o lumella bahlahisi ho hlahisa likarolo tse nang le lintlha tse rarahaneng le boleng bo tsitsitseng.

Die casting e etsa hore ho be le likarolo tsa tšepe tse nang le ho nepahala ho phahameng le lintlha tse ntle, tse kang libaka tse entsoeng ka holimo, ntle le ho hloka ts'ebetso e eketsehileng.

Ts'ebetso ena e sebelisoa haholo indastering e kang ea likoloi, sefofane le thepa ea bareki. E ts'ehetsa ho theoa ha likaroloana tse bobebe, tse matla le tse hananang le kutu, e etsa hore e be ea bohlokoa bakeng sa tlhahiso ea sejoale-joale.

Lintho Tse Sebelisitsoeng Ts'ebetsong

Khetho ea thepa e ama haholo ts'ebetso le boleng ba likarolo tsa tšepe tsa tšepe tsa setsebi. Baetsi ba sebelisa litšepe tse fapaneng le li-alloys, e 'ngoe le e' ngoe e fana ka thepa e ikhethang e loketseng lits'ebetso tse ikhethileng.

| Mofuta oa Boitsebiso | Thepa | Lisebelisoa |

|---|---|---|

| Aluminium Alloy 380 | E babatsehang castability, lightweight, corrosion resistance | Li-brackets tsa enjine, thepa ea ka tlung, likhechana tsa elektroniki |

| Aluminium Alloy B390 | Ho thothomela ho ikhethang le ho hanyetsa ho apara | Matlo a pompo, 'mele ea li-valve, li-impellers |

| Magnesium AZ91D | Karolelano e phahameng ea matla ho boima, ho hanyetsa ho bola | Likarolo tsa Powertrain, likarolo tsa mochini |

| Zinc Zamak 3 | Botsitso ba dimensional, boiketlo ba ho lahla | Likarolo tsa liphaephe, libapali tsa siling |

Aluminium ke khetho e ratoangka lebaka la karo-karolelano ea matla le boima ba 'mele le ho hanyetsa ho bola. Li-alloys tsa Magnesium li ratoa bakeng sa lits'ebetso tse bobebe, ha li-alloys tsa zinc li ipabola ka ho nepahala le liphetho tse boreleli.

Mehato ea Bohlokoa Ts'ebetsong ea ho Lahlela Lefu

Ts'ebetso ea "die casting" e kenyelletsa mehato e 'maloa ea bohlokoa, e' ngoe le e 'ngoe e kenya letsoho boleng ba sehlahisoa sa ho qetela.

- Tokisetso: Maholimo a hlobo a tlositsoe ho etsa bonnete ba hore ho ntšoa ha li-castings habonolo. Mohato ona o fokotsa mefokolo mme o netefatsa ho tlosoa ha bonolo.

- Ho tlatsa: Tšepe e qhibilihisitsoeng e kenngoa ka har'a hlobo tlas'a khatello e phahameng. Mohato ona o thibela shrinkage le porosity ka ho etsa bonnete ba ho tlatsa ka ho feletseng.

- Ejection: Lithapa tsa ejector li tlosa li-castings ho tloha hlobo. Sena se lumella lipotoloho tse potlakileng tsa tlhahiso le ho fokotsa tšenyo ea likarolo.

- Shakeout: Likarolo tsa likhahla li tlosoa ho li-castings tse phethiloeng. Mohato ona o netefatsa hore sehlahisoa sa ho qetela se kopana le litekanyetso tsa boleng.

Ho nepahala ha mehato ena ho etsa bonnete ba hore likarolo tsa tšepe tsa setsebi li kopana le lintlha tse hlokahalang bakeng sa ho tšoarella le ho sebetsa.

Melemo ea Melemo ea Metal Die Casting Parts

Ho Nepahalla le ho tsitsisa

Tsepe ea litsebishoa likarololi tsebahala ka ho nepahala ha tsona le ho tsitsa ha tsona ka mokhoa o ikhethang. Mokhoa oa ente ea khatello e phahameng o sebelisoang ts'ebetsong o netefatsa hore karolo e 'ngoe le e' ngoe e kopana le mamello e tiileng, e etsa hore e be e loketseng bakeng sa liindasteri tse hlokang meralo e rarahaneng. Mohlala, litharollo tsa CastMold's die-casting li hlahisa likarolo tse nepahetseng ka ho fetesisa, tse fokotsang tlhoko ea machining ea bobeli.

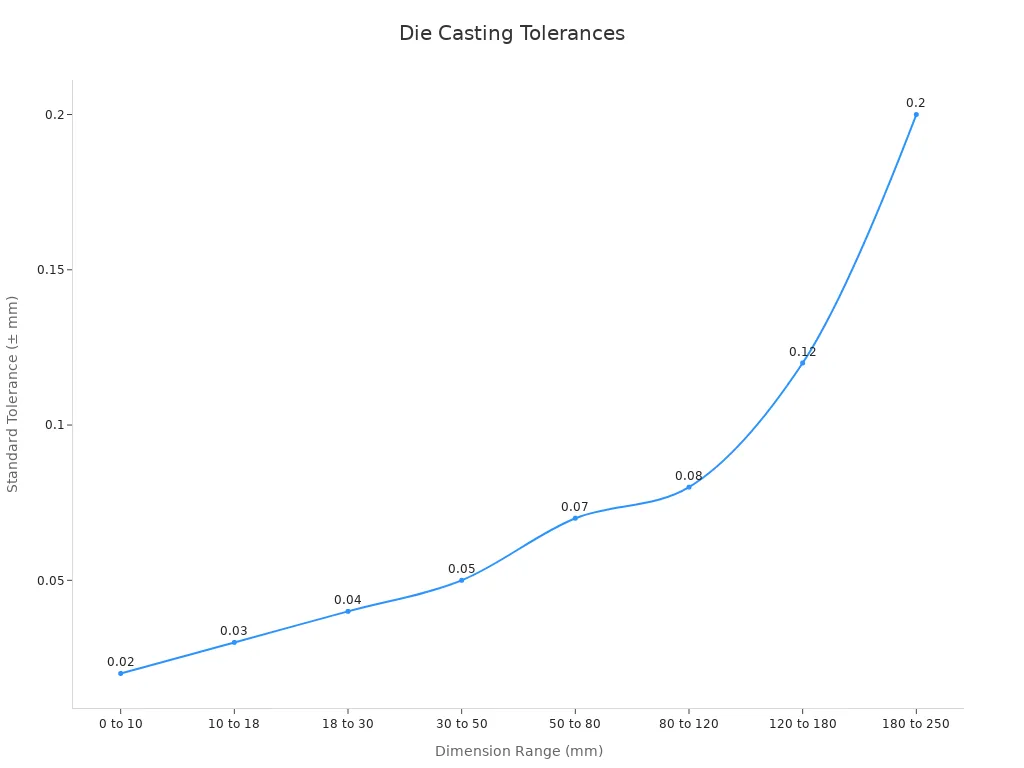

Bokhoni ba ho fumana mamello e tiileng ke letšoao la ho lahleheloa ke lefu. Ho nepahala hona ho bohlokoa bakeng sa lits'ebetso tseo le liphapang tse nyane li ka sitisang ts'ebetso.

| Boemo ba motheo (mm) | Mamello e Tloaelehileng (± mm) |

|---|---|

| 0 ho ea ho 10 | 0.02 |

| 10 ho isa ho 18 | 0.03 |

| 18 ho isa ho 30 | 0.04 |

| 30 ho isa ho 50 | 0.05 |

| 50 ho isa ho 80 | 0.07 |

| 80 ho isa ho 120 | 0.08 |

| 120 ho isa ho 180 | 0.12 |

| 180 ho isa ho 250 | 0.2 |

Sebaka se boreleli se fihlelletsoeng ka "die casting" se eketsa boleng ba sehlahisoa sa ho qetela. Sena se felisa tlhokahalo ea ts'ebetso e pharaletseng ea morao-rao, ho boloka nako le litšenyehelo ha ho ntse ho netefatsa hore ho na le sephetho se bonahalang se ipiletsang.

Katleho ea Litšenyehelo Bakeng sa Tlhahiso e Kholo

Die casting e fana katharollo e theko e boimabakeng sa ho hlahisa likarolo tse kholo tsa tšepe. Ts'ebetso e sebelisa lisebelisoa tse ikemetseng le tse ka sebelisoang hape ho fokotsa litšenyehelo tsa tlhahiso. Matsete a pele ho li-automation a kanna a bonahala a phahame, empa a lebisa polokelong e kholo mosebetsing le ts'ebetsong e eketsehileng ha nako e ntse e ea.

| Ntlha | Tlhaloso |

|---|---|

| Material Recyclability | Lisebelisoa tse ka sebelisoang hape li fokotsa litšenyehelo le ho ikamahanya le lipheo tsa moshoelella. |

| Tšebeliso ea Matla | Tšebeliso e ntlafalitsoeng ea matla mochining e theola litšenyehelo tsa ts'ebetso. |

| Automation Investments | Automation e fokotsa litšenyehelo tsa basebetsi mme e eketsa lebelo la tlhahiso. |

| Tsamaiso ea Matlakala le Litšila | Tsamaiso e sebetsang hantle ea litšila e fokotsa tahlehelo ea thepa le litšenyehelo. |

| Mehato ea Taolo ea Boleng | Liteko tse matla tsa boleng li fokotsa liphoso, li boloka nako le lisebelisoa. |

Ho ata ha die casting ho etsa hore ho be molemo haholo bakeng sa indasteri e kang ea likoloi le tsa elektroniki, moo tlhahiso ea boleng bo holimo e leng bohlokoa. Ka ho fokotsa litšila le ho ntlafatsa tšebeliso ea matla, bahlahisi ba ka finyella melemo ea moruo le ea tikoloho.

Durability le Matla a Likaroloana

Likarolo tsa profeshenale tsa metal die casting li ketekoa ka lebaka la ho tšoarella ha tsona le matla a tsona a mochini. Ts'ebetso e hlahisa likarolo tse nang le thepa e thata le e tsitsitseng, e etsang hore e tšoanelehe bakeng sa lits'ebetso tse hlokang. Mohlala, tlhahlobo ea mochini, ho kenyelletsa le liteko tsa ho ba thata le phello ea Charpy, e tiisa matla le ts'epahalo ea likarolo tsa die-cast.

Liindasteri tse kang sefofane le likoloi li itšetlehile ka likarolo tsa die-cast bakeng sa bokhoni ba tsona ba ho mamella maemo a feteletseng ntle le ho senya ts'ebetso.

Matla a mokhathala a litšepe tsa die-cast a eketsa ho tšoarella ha tsona, ho netefatsa ts'ebetso ea nako e telele le tlas'a khatello ea maikutlo e sa khaotseng. Sena se ba etsa khetho e ratoang bakeng sa lits'ebetso tsa bohlokoa joalo ka likarolo tsa enjene le likarolo tsa meralo.

Ka ho kopanya matla, ho tšoarella, le ho nepahala, die casting e fana ka likarolo tse fihlelang litlhoko tse matla tsa liindasteri tsa sejoale-joale.

Likopo tsa likarolo tsa Professional Metal Die Casting

Indasteri ea Likoloi

Lefapha la likoloi le itšetlehile haholo ka likarolo tsa tšepe tsa litsebi bakeng sa ho nepahala le ho tšoarella ha tsona. Ha tlhahiso ea likoloi tsa lefats'e e fihla ho li-unit tse ka bang limilione tse 85 ka 2022, tlhoko ea likarolo tsa die-cast e ntse e le matla. Baetsi ba sebelisa mahlale a tsoetseng pele joalo ka automation le digitalization ho fihlela litlhoko tse tsoelang pele tsa indasteri, haholo bakeng sa likoloi tsa motlakase le meralo e bobebe. Litlhahiso tse kang "giga casting" ea Ryobi bakeng sa likarolo tse kholo tsa 'mele oa EV le mechine e meholo ea UBE Corporation e totobatsang maikutlo a lekala holim'a katleho le ho fokotsa litšenyehelo. Lintlafatso tsena li netefatsa hore likarolo tsa die-cast li fihlela litlhoko tse thata tsa likoloi tsa sejoale-joale, ho kenyeletsoa matla, phokotso ea boima le ho hanyetsa ho bola.

Sepakapaka le Tšireletso

Sebakeng sa sefofane le ts'ireletso, die casting e bapala karolo ea bohlokoa ho hlahiseng likarolo tse bobebe empa tse tšoarellang. Mekhoa e tsoetseng pele ea li-alloys le vacuum die casting e fokotsa boima ba likarolo, e ntlafatsa ts'ebetso ea mafura ka 20%. Mokhoa ona o tiisa hore likaroloana li khona ho mamella likhatello tse feteletseng tsa ho fofa ha li ntse li kopana le litekanyetso tse thata tsa tšireletso.

| Molemo | Tlhaloso | Tšusumetso ho Aerospace le Tšireletso |

|---|---|---|

| Lisebelisoa tse bobebe | Li-alloys tse tsoetseng pele le vacuum die casting li fokotsa boima ba 'mele. | E ntlafatsa ts'ebetso ea mafura ka 20%. |

| Matla le ho tšoarella | E netefatsa hore likarolo li khona ho mamella khatello ea sefofane le litekanyetso tsa polokeho. | E finyella litlhoko tse phahameng tsa tšireletso. |

| Matla a Mafura | Ho fokotsa boima ba 'mele ho lebisa tšebelisong e ntle ea mafura. | E bohlokoa bakeng sa ho boloka litšenyehelo tsa ts'ebetso. |

Melemo ena e etsa hore ho lahlela lefu e be ntho ea bohlokoa bakeng sa ho etsa lisebelisoa tsa bohlokoa tsa sefofane le ts'ireletso.

Elektronike le Thepa ea Bareki

Die casting e boetse e ipabolaindastering ea lisebelisoa tsa elektroniki le thepa ea bareki. E fana ka likarolo tse matla, tse ka tšeptjoang bakeng sa lisebelisoa tsa motlakase, likarolo tse tšoarellang tsa lisebelisoa tsa lapeng, le lisebelisoa tse sebetsang empa tse khabisitsoeng bakeng sa thepa ea ka tlung.

| Indasteri | Melemo ea Die Casting Parts |

|---|---|

| Indasteri ea Motlakase | Likarolo tse matla tsa motlakase bakeng sa litsamaiso tse tšepahalang |

| Indasteri ea Lisebelisoa | Likarolo tse tšoarellang bakeng sa lisebelisoa tsa lapeng li matlafatsa katleho |

| Indasteri ea Thepa | Lisebelisoa tse sebetsang le tse khabisitsoeng bakeng sa boipiletso bo botle |

Ka ho kopanya ho nepahala, ho tšoarella, le ho feto-fetoha ha maemo, likarolo tsa tšepe tsa profeshenale li kopana le litlhoko tse fapaneng tsa liindasteri tsena.

Ho Khetha Tharollo e Nepahetseng ea Metal Die Casting

Ho Lekola Boitsebelo le Boiphihlelo

Ho khetha moetsi ea nepahetseng ho qala ka ho lekola boiphihlelo le boiphihlelo ba bona. Likhamphani tse nang le tsebo ea indasteri ea lilemo tse mashome hangata li fana ka litholoana tse phahameng. Mohlala, Dynacast e na le boiphihlelo ba lilemo tse fetang 80 ho hlahisa likarolo tse nepahetseng tsa tšepe bakeng sa likarolo tse fapaneng. Ka mokhoa o ts'oanang, A&B e hira lienjineri tse hloahloa tse khonang ho sebetsana le meralo e rarahaneng, e netefatsang liphetho tsa boleng bo holimo. Baetsi ba kang Castingod le Golden Pond Metal Die Casting Co., Ltd. ba bontša botšepehi le bokhoni ka ho laola merero e rarahaneng le ho kenya ts'ebetsong mehato e tiileng ea ho laola boleng.

Boitseanape bo netefatsa hore bahlahisi ba ka sebetsana le mathata a ikhethang, athe boiphihlelo bo tiisa ts'ebetso e ts'oanang ho merero eohle.

Ha u lekola mofani oa thepa, nahana ka rekoto ea bona le litšupiso. Nalane e matla ea ho fana ka likarolo tsa boleng e bonts'a boitlamo ba bona ba bokhabane.

Ho Lekola Theknoloji le Thepa

Theknoloji ea morao-rao e bapala karolo ea bohlokoa ho hlahiseng boleng bo phahamenglikarolo tsa die-cast. Litsamaiso tse ikemetseng li ntlafatsa katleho le ho nepahala, ho fokotsa litšenyehelo tsa basebetsi le ho fokotsa liphoso tsa batho. Liroboto li tsamaisa ente le lits'ebetso tsa ejection, li netefatsa boleng bo tsitsitseng nakong eohle ea tlhahiso. Software e tsoetseng pele ea ketsiso e bolela esale pele liphoso le ho ntlafatsa ts'ebetso ea ho etsa, e nolofalletsang prototyping pele ho tlhahiso ea 'mele.

Baetsi ba sebelisang AI le ho ithuta ka mochini ba ka beha leihlo le ho ntlafatsa ts'ebetso ka nako ea nnete. Lintlafatso tsena li ntlafatsa polokeho, lebelo le ho nepahala, e leng se etsang hore e be tsa bohlokoa haholo bakeng sa likarolo tsa tšepe tsa tšepe.

Bohlokoa ba Tiisetso ea Boleng le Lisetifikeiti

Setifikeiti se netefatsa sa moetsiboitlamo ba bolengle ho latela maemo a indasteri. Litifikeiti tsa ISO li netefatsa ho ipapisa le litekanyetso tsa machabeng, athe litekanyetso tsa Amerika joalo ka NADCA le ASTM li netefatsa ts'epo. Teko ea metallurgic e netefatsa thepa ea mochini, ha tlhahlobo ea sebopeho sa lik'hemik'hale e netefatsa boleng ba thepa.

Mekhoa ea tlhahlobo e matla, joalo ka liteko tsa matla le boima ba 'mele, e netefatsa ho tšoarella ha likarolo tsa die-cast.

Lisetifikeiti tse kang ISO 9001 le AS9100 li bohlokoa haholo liindastering tse hlokang likarolo tse sa tsotelleng polokeho, joalo ka sefofane le ts'ireletso. Matšoao ana a fana ka kholiseho ho bokhoni ba moetsi ba ho fana ka lihlahisoa tse tsitsitseng, tsa boleng bo holimo.

Likarolo tsa profeshenale tsa tšepe li bapala karolo ea bohlokoa tlhahisong ea sejoale-joale. Karo-karolelano ea matla a bona ho boima ba 'mele e ntlafatsa ts'ebetso indastering e kang ea likoloi, athe metsi a tsona a tšehetsa meralo e rarahaneng le ho fokotsa litšenyehelo tsa thepa. Ho lahlela ka khatello e phahameng ho netefatsa mefokolo e fokolang, ho etsa hore lihlahisoa li tšepahale li be li sebetse hantle. Ho khetha moetsi ea tšepahalang ho netefatsa litharollo tsa boleng le tse lokiselitsoeng litlhoko tse ikhethang. Litsebi tsa boeletsi li thusa likhoebo ho fumana liphetho tse nepahetseng.

LBH

Ke liindasteri life tse ruang molemo ka ho fetisisa ho tsoa ho metal die casting?

Liindasteri tsa likoloi, tsa sefofane, le tsa elektroniki li rua molemo haholo. Ba itšetlehile ka die casting bakeng sa ho nepahala, ho tšoarella, le tlhahiso e theko e tlaase ea likarolo tsa boleng bo holimo.

Ho etsa die casting ho netefatsa ho nepahala ha dimensional joang?

Ente ea khatello e phahameng e bopa tšepe hore e be libopeho tse nepahetseng. Ts'ebetso ena e fokotsa ho kheloha, ho etsa bonnete ba hore likarolo li kopana le mamello e tiileng ntle le ho hloka ts'ebetso e pharaletseng ea kamora ts'ebetso.

Na seea-le-moea se ka sebelisa lisebelisoa tse tsosolositsoeng?

Ee, bahlahisi hangata ba sebelisa litšepe tse ka sebelisoang hape joalo ka aluminium le zinki. Mokhoa ona o fokotsa litšila, o theola litšenyehelo, 'me o tšehetsa lipakane tsa ts'ebetso.

Ka: haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Mohala:

Lithekiso: 0086-134 8641 8015

Tšehetso: 0086-574 8669 1714

Nako ea poso: Apr-22-2025