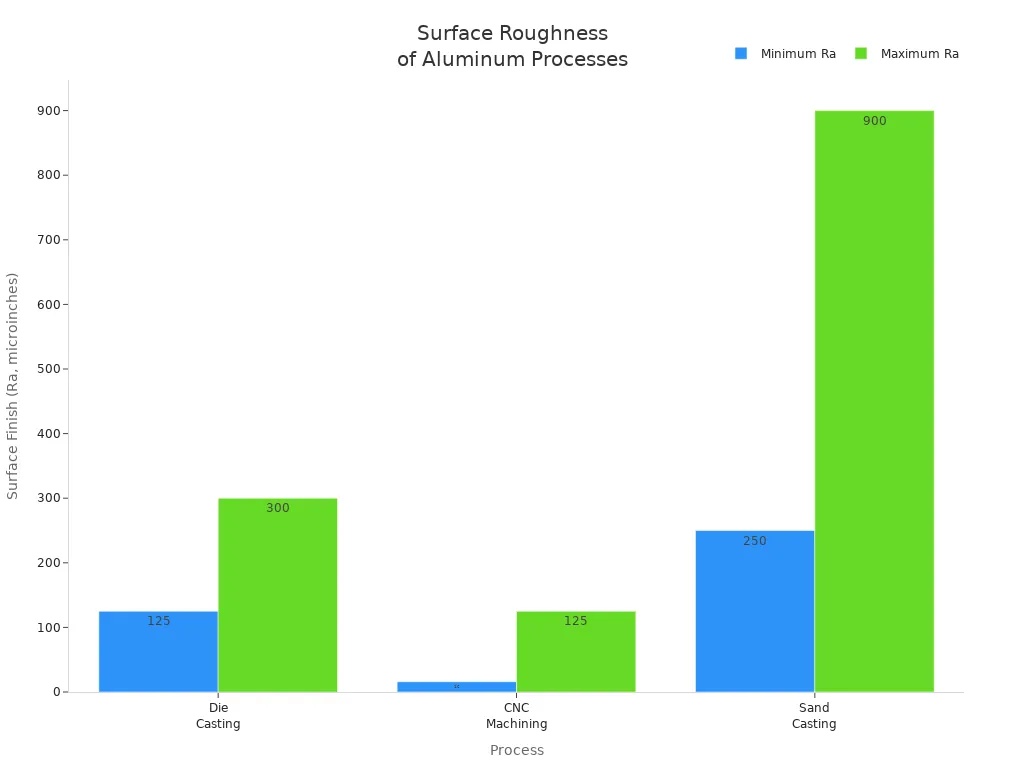

Lokacin da kake kallon sassan simintin aluminum da aka yi amfani da su a cikimota or sadarwamasana'antu, kuna son gamawa mai santsi, mara lahani. CNC machining yana ba ku wannan gefen. Yana ɗaukar m, simintin gyare-gyare kuma yana sanya su sumul da madaidaici. Kawai duba bambancin:

| Tsari | Kammala saman saman (Ra) |

|---|---|

| Mutuwar Casting | 125-300 microinches |

| Farashin CNC | 16-125 microinches |

| Yashi Casting | 250-900 microinches |

Kuna iya ganin yadda mashin ɗin CNC ke taimaka muku cimma kyakkyawan ƙarewa, yana sa kowane ɓangaren ya yi kama da aiki mafi kyau.

Key Takeaways

- CNC machining muhimmanciinganta farfajiyar gamawana simintin gyaran gyare-gyaren aluminium, suna samun mafi ƙarancin ƙarewa tsakanin 16 zuwa 125 microinches Ra.

- Yin amfani da CNC milling da juyi matakaiyana haɓaka daidaitoda daidaito na sassa, tabbatar da m haƙuri da mafi kyau aiki.

- Dabarun gamawa na ci gaba kamar polishing da anodizing ba kawai inganta bayyanar ba amma har ma ƙara ƙarfin ƙarfi da juriya na lalata.

Ƙayyadaddun Ƙirar Ƙarshen Sama a cikin Cast Aluminum Die Casting

Matsalolin gama gari a cikin Aluminum Cast

Lokacin da kuke aiki da simintin aluminum, zaku iya lura da wasu kurakurai a saman. Waɗannan gazawar na iya shafar yadda sassanku suke kama da aiki. Ga 'yan batutuwa da za ku iya gani:

- Ƙarshen saman yana taka muhimmiyar rawacikin tsawon lokacin da sashinku zai kasance.

- Idan ƙarewar bai yi daidai ba, juriya na lalata ya ragu.

- Wani lokaci, ɓangaren ba ya da kyau kamar yadda kuke so.

Hakanan zaka iya gano nau'ikan porosity iri biyu. Porosity na iskar gas yana faruwa ne lokacin da iska ko hydrogen suka kama cikin karfe, suna barin ƙananan ramuka zagaye. Ƙunƙarar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaƙƙarfar ƙaho ne lokacin da ƙarfe ya yi sanyi da raguwa.

Haƙuri da Ƙalubalen dagewa

Kuna son sassan ku su dace daidai kowane lokaci. Daidaitaccen simintin gyare-gyaren aluminium yawanci yana ba ku haƙuri tsakanin ± 0.05 mm da ± 0.10 mm. Don ingantattun ayyuka, zaku iya sauka zuwa ± 0.01 mm. Matsayin masana'antu kamar ISO 8062-3 da NADCA suna taimakawa jagorar abin da zai yiwu. Har yanzu,buga wadanda m tolerancesna iya zama mai tauri, musamman idan kuna buƙatar sakamako iri ɗaya ga kowane bangare.

Ƙuntatawa na Geometric a cikin Casting Die

Die simintin gyare-gyare yana aiki mafi kyau don wasu siffofi. Idan kuna buƙatar kusurwoyi masu kaifi, ramuka masu zurfi, ko bangon bakin ciki, za ku iya shiga cikin matsala. Tsarin yana ƙayyadaddun ƙayyadaddun ɓangaren ɓangaren ku zai iya zama. Wani lokaci, dole ne ku canza ƙirar ku ko ƙara ƙarin matakai don samun abubuwan da kuke so.

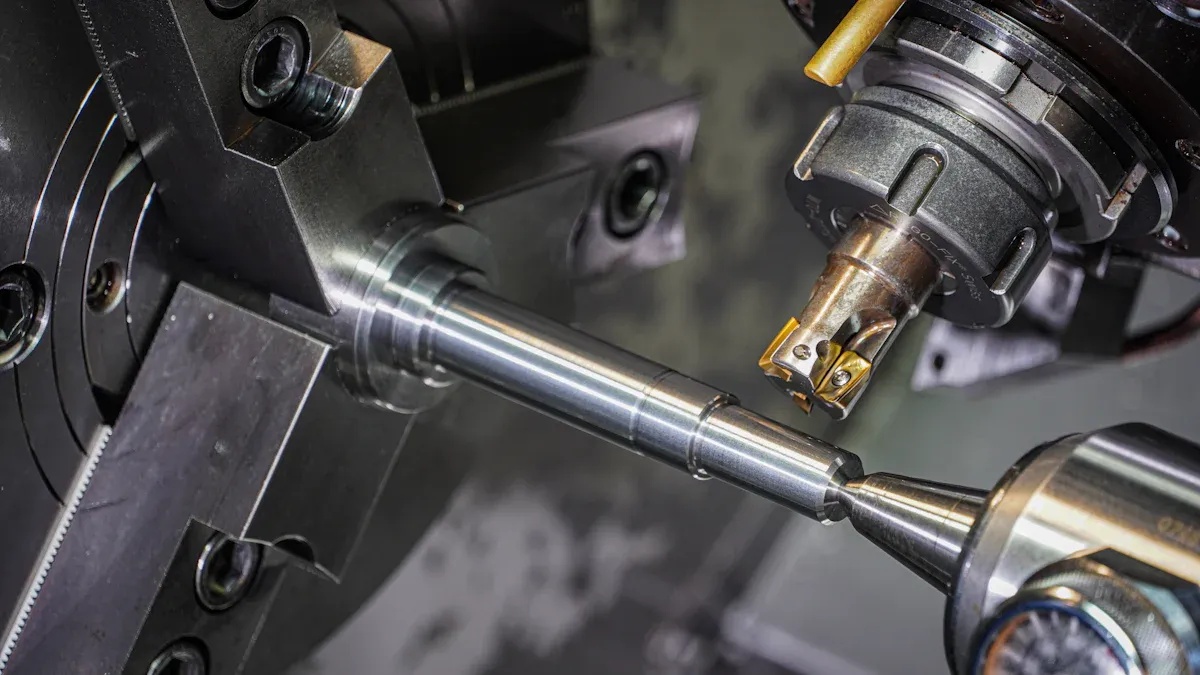

Hanyoyin Injin CNC don haɓaka Aluminum Cast

Milling for Flatness da Smooth surfaces

Lokacin da kake son nakajefa aluminum sassadon duba da jin santsi, CNC milling shine aikin ku don aiwatarwa. Injin niƙa suna amfani da kaifi, kayan aikin jujjuya don kawar da tarkace da haifar da lebur, har ma da filaye. Kuna iya dogaro da milling CNC don gyara wuraren da ba su dace ba kuma ku tabbata sassan ku sun dace da juna daidai. Wannan tsari na iya kaiwa ga m haƙuri, wani lokacin daidai kamar ± 0.005 mm. Wannan yana nufin sassan ku za su sami daidaiton kauri da santsi, wanda ke da mahimmanci ga abubuwa kamar murfin injin ko madaidaicin injin.

Flatness babban abu ne. Yana gaya muku yadda santsi da ma saman yake. Idan kuna buƙatar sassa biyu don dacewa tare ba tare da gibi ba, kuna son duka biyu su kasance masu lebur gwargwadon yiwuwa. CNC milling yana taimaka maka isa wurin ta hanyar cire kututtuka da tsomawa daga simintin. MIC-6 aluminum, alal misali, yana da tsari na hatsi na musamman wanda ya sa ya fi sauƙi don cimma kyakkyawan ƙare lokacin da kuka yi amfani da shi.

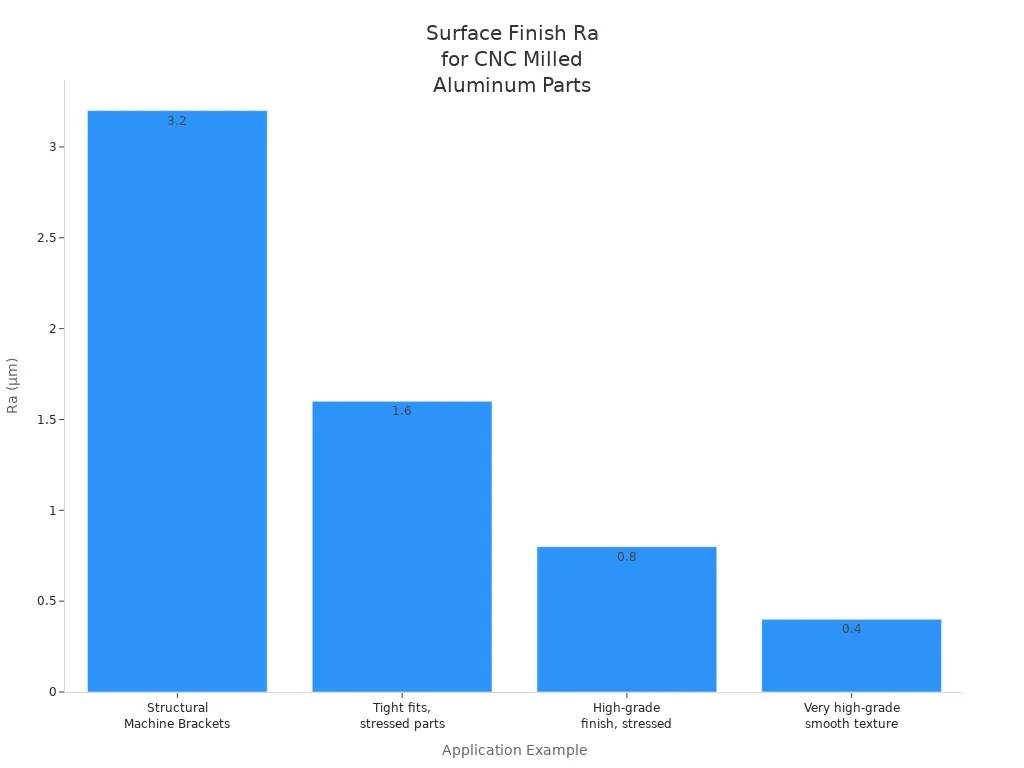

Kuna iya zaɓar matakan ƙarewa daban-daban, dangane da abin da ɓangaren ku ke buƙata. Ga saurin kallon abin da zai yiwu:

| Ra (µm) | Misalai na Aikace-aikace | Mabuɗin Halaye |

|---|---|---|

| 3.2 | Rubutun Injin Tsari, Murfin Injin Mota, Gabaɗaya Kayan Kayan Aiki, Chassis Injin | Amfani da aiki, matsakaicin matsananciyar damuwa |

| 1.6 | Matsakaicin madaidaici, sassan ƙarƙashin damuwa | Alamar yanke da ake gani kaɗan, ƙara farashin samarwa da kashi 2.5% |

| 0.8 | Ƙarshe mai daraja don sassa masu damuwa | Yana buƙatar izinin ƙarewa, yana ƙara 5% zuwa farashin samarwa |

| 0.4 | Sosai high-sa santsi laushi | Babu alamun yanke da za a iya gani, yana ƙara har zuwa 15% zuwa farashin samarwa |

Idan kana buƙatar ɓangaren da ya yi kama da kyau kuma yana aiki da kyau, CNC milling yana ba ku iko don samun gamawa da kuke so.

Juya don Daidaiton Silinda

Juyawar CNC ita ce hanya mafi kyau don yin sassa na zagaye ko cylindrical daga simintin aluminum. Injin yana jujjuya sashin ku yayin da kayan aikin yanke ke siffata shi. Wannan tsari cikakke ne don yin abubuwa kamar shafts, bushings, ko kowane ɓangaren da ke buƙatar zama daidai gwargwado.

Kuna samun daidaito mai ban mamaki tare da juyawa CNC. Na'urar na iya ɗaukar haƙuri kamar ± 0.0001 inci (2.54 microns). Wannan yana nufin kowane bangare da kuka yi zai zama kusan daidai. Ba sai ka damu da kura-kurai daga hannun mutane ba, domin kwamfuta ce ke sarrafa komai. Wannan babban abu ne ga masana'antu kamar motoci da sararin samaniya, inda ko da ƙananan kurakurai na iya haifar da matsala.

Ga kwatance mai sauri:

| Siffar | Canjin CNC | Juyawar Gargajiya |

|---|---|---|

| Haƙuri | ± 0.0001 inci (2.54 microns) | Gabaɗaya sassaucin haƙuri |

| Maimaituwa | High, m inganci | Mai canzawa, mai saurin kamuwa da kuskuren ɗan adam |

| Ƙarshen Sama | Mafi girma, sau da yawa babu sakandare | Yana iya buƙatar ƙarin ƙarewa |

| Kuskuren Dan Adam | Rage | Haɗarin kurakurai mafi girma |

Tare da juyawa CNC, kuna samun santsi, daidaito, da sakamako mai maimaitawa kowane lokaci.

Gyaran gogewa da Ƙarfafa hanyoyin Ƙarshe

Bayan niƙa ko juyawa, kuna iya son sassan simintin aluminum ɗinku su yi kyau sosai. Wannan shine inda gogewa da haɓaka ci gaba ke shigowa. Waɗannan hanyoyin na iya sa sassanku su haskaka, santsi, ko ba su wani rubutu na musamman.

Ga wasu shahararrun zaɓuɓɓukan gamawa:

- Gyaran injina:Machines suna niƙa kuma suna goge saman don cire ƙananan kusoshi da fashe.

- Kemikal goge:Sinadarai sun santsi da ƙasa ta hanyar cire Layer oxide.

- Electrochemical polishing:Yana amfani da wutar lantarki da sinadarai don ƙarewa mai kyau.

- Daidaitaccen goge goge na inji:Matakai da yawa tare da madaidaicin kayan aiki don ƙarin santsi.

- Madaidaicin gogewa:Advanced tech kamar Laser ko ion biams ga smoothest gama yiwu.

- Ƙullawar sararin sama:Yana dawo da juriya na lalata bayan gogewa, yawanci yana amfani da anodizing.

Hakanan zaka iya amfani da hanyoyi kamar ƙarewar girgiza da harbin iska mai ƙarfi. Ƙarshen rawar jiki yana sanya sassan ku a cikin kwano tare da kafofin watsa labarai na musamman waɗanda ke goge su a hankali kuma suna lalata su. Shot fashewa yana amfani da barbashi masu sauri don ƙirƙirar ɗaki ɗaya, saman matte. Wadannan fasahohin suna taimakawa shirya sassan ku don sutura ko kawai sanya su suyi kyau.

Idan kuna son ƙara launi ko ƙarin kariya, kuna iya gwadawa:

- Anodizing:Yana ƙara tauri, launi mai launi wanda ke ƙin lalacewa da lalata.

- Rufe foda:Yana ba da ƙarfi, har ma da ƙare a kusan kowane launi.

- Yashi:Yana ƙirƙira kyan gani mai matte kuma yana shirya saman don ƙarin ƙarewa.

Ƙarshen injina da sinadarai kowanne yana da nasa kamanni da fa'idarsa. Ga jagora mai sauri:

| Ƙarshen Makanikai | Fitowar Sama | Hanyar aikace-aikace | Amfanin gama gari |

|---|---|---|---|

| Goge | Direction, satin gama | Gwargwadon goge-goge | Tsarin gine-gine |

| goge baki | Santsi, mai tunani | Progressive abrasives | Aikace-aikace na ado da kariya |

| Ƙarshen fashewa | Uniform matte | Barbashi masu saurin gudu | Pre-maganin shafawa |

Gyara Matsalolin Casting tare da CNC Machining

Wani lokaci, simintin gyaran gyare-gyaren aluminum suna fitowa daga cikin ƙira tare da ƙananan lahani.CNC machining na iya gyarawadayawa daga cikin wadannan batutuwa, don haka ba sai ka jefar da bangaren ba.

Mafi yawan lahani da za ku iya gyara sun haɗa da:

- Porosity:Ƙananan ramuka ko aljihu waɗanda iskar gas ta kama. CNC machining iya cire wadannan daga saman, sa bangaren da karfi da kuma zube-hujja.

- Lalacewar siffar:Matsaloli kamar sifofi mara kyau ko m gefuna. Injin CNC na iya datsa da sake fasalin waɗannan wuraren don dacewa da dacewa.

| Lalacewar simintin gyare-gyare | Bayani |

|---|---|

| Porosity | Yana faruwa lokacin da iskar gas ya haifar da aljihu ko ramuka, yana haifar da zubewa. |

| Lalacewar Siffa | Tashi daga kuskure ko murdiya, yana haifar da abubuwan da basu cika ba. |

Ta amfani da injina na CNC, zaku iya juya ɓangaren simintin simintin gyaran gyare-gyaren aluminium zuwa wani yanki mai inganci wanda ya dace da ainihin bukatunku.

Fa'idodin CNC Machining don Cast Aluminum Parts

Ingantattun Bayyanar da Ingantattun Kayayyakin gani

Kuna son sassan ku su yi kama da kaifi da ƙwararru. CNC machining yana taimaka muku cimma hakan. Tare da ci-gaba dabarun gamawa, zaku iya zaɓar ainihin kamannin da kuke so don abubuwan haɗin aluminum na simintin ku. Duba wasu shahararrun zaɓuɓɓuka:

| Dabaru | Bayani | Amfani |

|---|---|---|

| Ƙwaƙwalwar Ƙwaƙwalwa | Yana amfani da kafofin watsa labarai masu lalata don matte gama | Yana kawar da alamun kayan aiki, inganta mannewa fenti, jin daɗi |

| Rufin Foda | Yana shafa foda kuma yana warkar da zafi | Babban juriya na lalata, mannewa mai ƙarfi, yawancin ƙarewa |

| Gyaran madubi | Daidaitaccen kammalawa don haske mai haske | Yana rage gogayya, yana haɓaka juriya na lalata, tsabtar gani |

| Goge Garewa | Ƙirƙirar ƙirar hatsi iri ɗaya | Nau'in rubutu na musamman, yana kiyaye girma |

| Anodizing | Yana gina Layer oxide akan aluminum | Ƙarin juriya na lalata, ƙasa mai wuya, zaɓuɓɓukan launi |

Waɗannan hanyoyin suna sa sassan ku su yi fice kuma su daɗe.

Ingantattun Fitsari, Aiki, da Aiki

Kuna buƙatar sassan ku don dacewa da juna daidai. CNC machining yana ba da juriya mai ƙarfi da daidaito daidai, wanda ke nufin ƙarancin matsalolin taro da ingantaccen aiki. Ga yadda CNC machining ke taimakawa:

| Gudunmawar CNC Machining | Bayani |

|---|---|

| Takaitaccen Hakuri | Sassan sun haɗu da ma'auni daidai don haɗuwa mai santsi |

| Daidai Daidai | Abubuwan da suka dace sun dace da juna, rage kurakurai |

| Babban Madaidaicin CAD Modeling | Yana tabbatar da ƙirar ku ta dace da samfurin ƙarshe |

Lokacin da sassan ku suka dace daidai, injin ɗinku suna aiki mafi kyau kuma suna daɗe.

Ƙara Dorewa da Rayuwar Sabis

Kuna son sassan simintin aluminium ɗinku don ɗaukar ayyuka masu wahala kuma su ci gaba da aiki. CNC machining yana taimakawa ta hanyar sarrafa zafi, lalacewa na kayan aiki, da sigogin injina. Wannan yana kiyaye sassan ku ƙarfi da aminci. Anan akwai wasu hanyoyin CNC machining na haɓaka dorewa:

- Yana amfani da yankan ruwa don sarrafa zafi da kare filaye

- Yana kiyaye babban saurin yankewa tare da sanyaya mai dacewa

- Yana daidaita saitunan injina don hana warping ko murdiya

Tukwici: Lokacin da kuke amfani da mashin ɗin CNC, kuna samun sassan da suka daɗe kuma suna aiki mafi kyau, har ma a cikin wuraren da ake buƙata.

CNC machining yana ba ku sassauƙa, ƙarin amintattun sassa na simintin aluminum. Kuna samun mafi kyawun kamanni, madaidaicin madaidaici, da abubuwan haɗin gwiwa masu dorewa. Yawancin masana'antu sun dogara da wannan tsari:

| Masana'antu | Dalilin Amfani |

|---|---|

| Motoci | Motsi mai nauyi, injin dorewa da sassan chassis |

| Jirgin sama | Matsakaicin ƙarfi-zuwa nauyi ga jirgin sama |

| Gina | Juriya na lalata ga tsarin |

| Marine | Ƙananan nauyi, abubuwan da ke jure lalata |

| Kayan lantarki | Madaidaicin sassa don na'urori |

| Kayayyakin Mabukaci | Amfani da yawa a cikin samfuran da yawa |

| Kayan Aikin Lafiya | Na'urori marasa guba, masu sauƙin-bakara |

Saka hannun jari a kammala CNC yana taimaka muku saduwa da mafi girman matsayi kowane lokaci.

FAQ

Wane ƙarewar saman za ku iya tsammanin bayan CNC machining simintin aluminum?

Yawancin lokaci kuna samun ƙarancin ƙarewa tsakanin 16 zuwa 125 microinches Ra. CNC machining yana kawar da tabo mara kyau kuma ya bar sassan ku suna neman gogewa.

Tukwici: Kuna iya zaɓar mafi kyawun ƙare don ayyuka na musamman.

Shin CNC machining inganta ƙarfin simintin sassa aluminum?

Ee, kuna samun sassa masu ƙarfi. CNC machining yana kawar da wurare masu rauni da lahani, don haka abubuwan haɗin ku suna daɗe da yin aiki mafi kyau.

Za a iya hada CNC machining tare da sauran karewa hanyoyin?

Lallai! Za ka iya amfani da CNC machining da farko, sa'an nan ƙara anodizing, foda shafi, ko polishing. Wannan yana ba ku kyan gani na al'ada da ƙarin kariya.

| Hanyar Karewa | Amfani |

|---|---|

| Anodizing | Juriya na lalata |

| Rufin Foda | Zaɓuɓɓukan launi |

| goge baki | Sama mai sheki |

Lokacin aikawa: Satumba-03-2025